Brushless motor vs brushed motor

Brushed motors use brushes to flow current inside the motor. Despite their low cost, they have drawbacks such as the need for regular maintenance, the risk of overheating, and the tendency to generate noise. Rabbit Air circumvents these drawbacks by using an advanced brushless DC motor with copper wire coils around the motor to drive current through the motor. This latest technology allows the motor to run quietly without overheating and reduces the need for regular maintenance.

Structural differences

brushed motor

The magnets and brushes are fixed, and the armature and commutator rotate together on the motor shaft inside the magnets.

1

Carbon brush

2

Magnet

3

Armature

4

Commutator

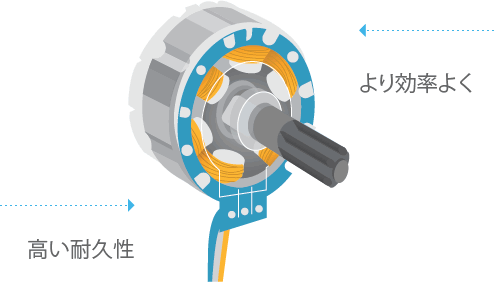

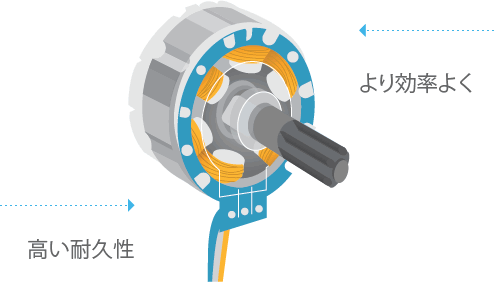

Brushless motor

Brushless motors use a small circuit board instead of brushes and a commutator to control the power flowing through copper wire coils. The arrangement of magnets and copper wire coils is also reversed from that of brushed motors.

1

Magnet

2

Armature

3

Electrical controller

Advantages of brushless motors

Brushless motors are highly efficient and durable:

-

Much StrongerThe copper wire coils are placed outside the motor, allowing the coils to be larger and more powerful.

-

SmarterWhile brushed motors run continuously at maximum speed, brushless motors can deliver current while adjusting resistance.

-

More efficient In the case of a brushless motor, there is no frictional resistance or voltage drop caused by contact between the rotating commutator and the brushes. Such physical contact results in continual power loss and brush wear.

Return to MinusA2 product description